Plating Processes That Maintain Functionality!

Various metal surface finishing techniques are available for production and prototype use. Nonetheless, not all of them fit into the operations, everything being equal. Many surface completions center around working on the style of your item. Others often further develop the item’s usefulness better, while some do both.

We offer a high level of diligence, experience, and precision required to perform electroplating correctly. It is contingent not only on the exacting specifications of the electrochemical process but also on thorough preparatory work that must be completed before the switch is activated. Thus, electroplating is host to a few imperfections because of the intricacy of the interaction.

Common Types Of Plating

Listed below are the most common method of plating available to us:-

Chrome Plating

Typically, chromic acid and trivalent chromium baths are used in this plating process to create an overlay on the metal parts. Improving the material’s aesthetics is the primary objective of chrome plating. However, chromium metal plating finishes also improve the material’s hardness and resistance to corrosion. These chrome-plated components can be used in industrial settings.

On occasion, it also helps to restore worn-out parts’ tolerances. Nickel Chrome Plating Service in Saudi Arabia is utilized more because Nickel is a standard metal for plating due to its utility in electroless plating. It improves appearance and resistance to wear. The best plating method for copper and aluminum is this one. Our company serves it as the fundamental plating for chromium.

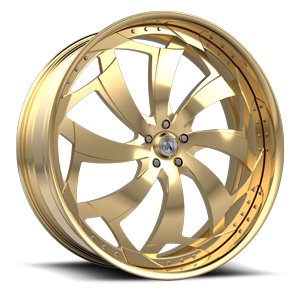

Gold Plating

Gold is famous for its high electrical conductivity and protection from oxidation. Gold plating is an easy way to give silver and copper metals these essential properties. Gold Plating Services in Saudi Arabia are widely used to increase the conductivity of electronic components like electrical connectors.

Copper Plating

At the point when your applications call for cost-effectiveness and high conductivity, copper plating is the best approach. This system typically fills in as the primary covering pre-treatment for the accompanying plated finish. It is one of the most widely used finishes for plating metal on electronic parts like circuit boards. It is a well-known decision due to its low material expense and plating productivity.

Conclusion

Metal plating is one of many materials and finishes that we provide. Our group of specialists works with you to make a custom metal-completing strategy. You can be sure of high-quality services, lower operating costs, and general satisfaction in this manner. When looking at metal plating finishes for your applications, you should look for people with experience and knowledge. Zouq Al-Khayal Steel Company is the best business that provides a perfect blend of both. We have extended periods of involvement by offering financially savvy surface completion answers for various enterprises.